Quartz can be divided into two different groups.

Because of the different initial raw materials, quartz can be divided into two different groups. If natural quartz is used as raw material, it is called fused quartz. If adopted

Silicon tetrachloride as a raw material is called fused quartz. The production method depends on the raw material. It can be divided into the following methods:

Electrofusion

Gas refining process

Synthetic method

Electrofusion

Electric melting is a common method of fusing quartz sand to produce quartz. The two methods of electric melting can be divided into arc melting and resistance melting furnace.

Arc melting: A voltage is formed between the two electrodes. When the voltage and current are high enough, the air discharges between the electrodes. Electron discharge, also known as plasma, can provide thousands of degrees of temperature, where the arc moves on the surface, and where the quartz sand on the surface melts into glass.

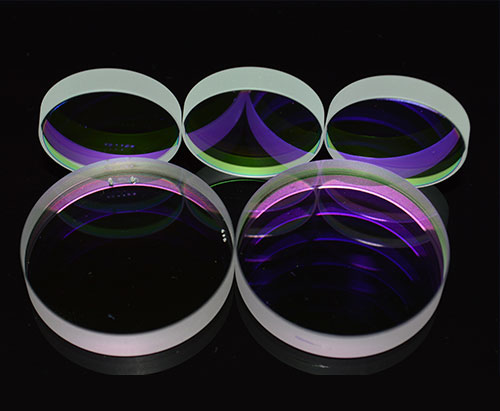

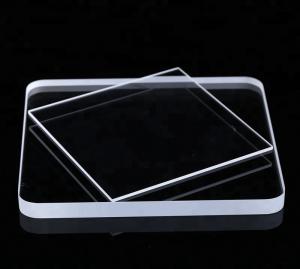

Depending on the size, purity and distribution of quartz particles, glass can be opalescent, transparent or translucent arc melting is often used in rotationally symmetrical glass objects. Resistance heating can be subdivided into continuous and discontinuous processes.

In a continuous process, quartz sand is poured from the end of the furnace, which consists of an electric heating module wound around a metal crucible.

Crucible is at or below normal atmospheric pressure to prevent refractory metal oxidation. The regular microcrystalline structure at 1800 degrees becomes an irregular glassy network structure. The melted material passes through the forming hole at the bottom of the crucible to produce rods, tubes or other products of various specifications.

Intermittent melting method, in which a large number of raw materials are placed in a vacuum furnace and refractories are reported all around, is used to produce large monomer materials.

Gas refining process

JNC quartz melts colorless crystals in hydrogen and oxygen. The basic concept of this process is that quartz sand enters high temperature flame. Crystalline particles in the flame melt and melt together to form quartz glass. There are different ways to remove them from the flame. One method is to attach the fused quartz droplets to the quartz rod, remove the quartz rod, and obtain a round bar. Another way is to collect fused quartz in a bowl, then through the hole at the bottom of the bowl, draw the glass of the desired shape, such as the barrel box. According to different parameters, transparent and milky white can also be produced.

Silicon tetrachloride as a raw material is called fused quartz. The production method depends on the raw material. It can be divided into the following methods:

Electrofusion

Gas refining process

Synthetic method

Electrofusion

Electric melting is a common method of fusing quartz sand to produce quartz. The two methods of electric melting can be divided into arc melting and resistance melting furnace.

Arc melting: A voltage is formed between the two electrodes. When the voltage and current are high enough, the air discharges between the electrodes. Electron discharge, also known as plasma, can provide thousands of degrees of temperature, where the arc moves on the surface, and where the quartz sand on the surface melts into glass.

Depending on the size, purity and distribution of quartz particles, glass can be opalescent, transparent or translucent arc melting is often used in rotationally symmetrical glass objects. Resistance heating can be subdivided into continuous and discontinuous processes.

In a continuous process, quartz sand is poured from the end of the furnace, which consists of an electric heating module wound around a metal crucible.

Crucible is at or below normal atmospheric pressure to prevent refractory metal oxidation. The regular microcrystalline structure at 1800 degrees becomes an irregular glassy network structure. The melted material passes through the forming hole at the bottom of the crucible to produce rods, tubes or other products of various specifications.

Intermittent melting method, in which a large number of raw materials are placed in a vacuum furnace and refractories are reported all around, is used to produce large monomer materials.

Gas refining process

JNC quartz melts colorless crystals in hydrogen and oxygen. The basic concept of this process is that quartz sand enters high temperature flame. Crystalline particles in the flame melt and melt together to form quartz glass. There are different ways to remove them from the flame. One method is to attach the fused quartz droplets to the quartz rod, remove the quartz rod, and obtain a round bar. Another way is to collect fused quartz in a bowl, then through the hole at the bottom of the bowl, draw the glass of the desired shape, such as the barrel box. According to different parameters, transparent and milky white can also be produced.

0086 13905125665

0086 13905125665  Contact person: Zhang Dongguang

Contact person: Zhang Dongguang